Behind every garment that catches your eye on the runway, on social media, or in your favorite store, there’s a complex and meticulous process that turns raw materials into a finished product. Today, we are taking you behind the scenes to show you what a typical day looks like for us, a clothing manufacturer in China.

Morning: Setting the Tone for the Day

While we may not have meetings every single day, but we always start the day making sure the team is on the same page. Whether it’s a quick check-in or just some quick updates, we take a moment to go over the plan for the day and address any issues early on. This helps keep everything running smoothly. The production manager plays an important role to in overseeing the production schedule, ensuring that everyone knows what needs to be done, and that our production schedule is being followed.

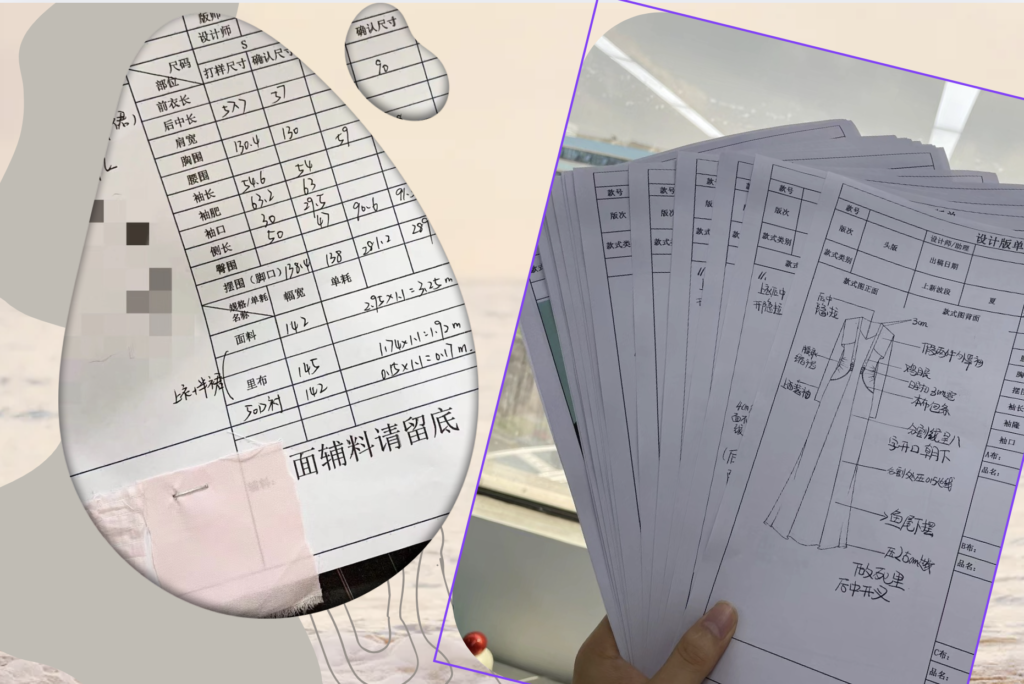

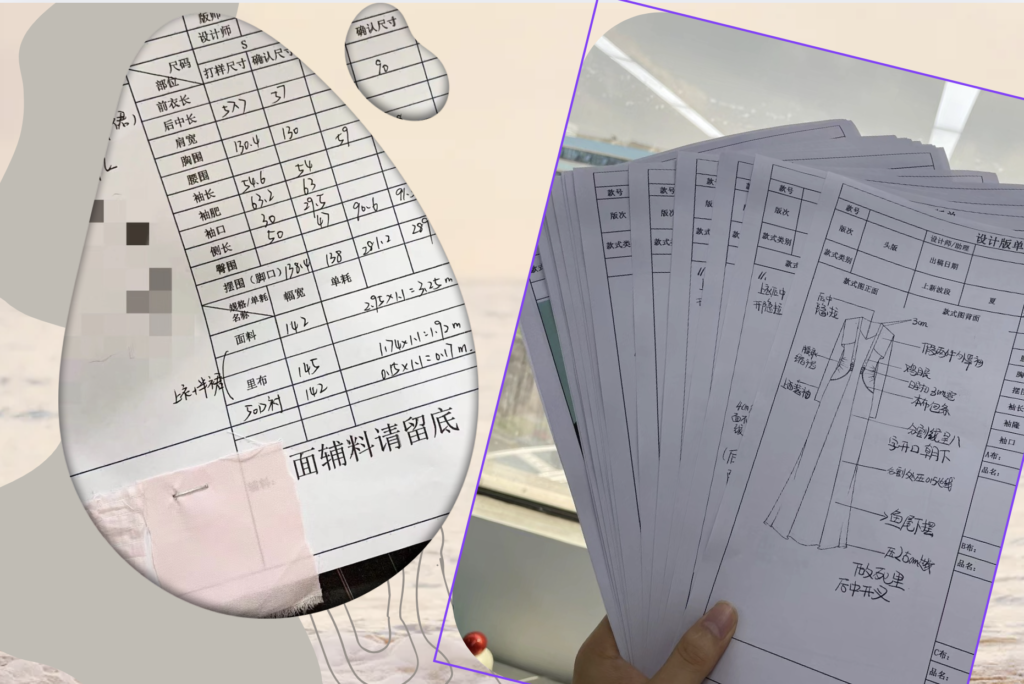

Tech Packs and Orders: The Blueprint of the Day

Order, tech pack or any related files are translated and handed over to our team members. For instance, the tech pack/specification is a blueprint for the entire production process, detailing everything from fabric specifications to construction details. If there are any unclear points, we reach out to the client right away to make sure we’ve got everything just right. We make sure to keep clients informed by regularly updating them on the status of their orders/projects.

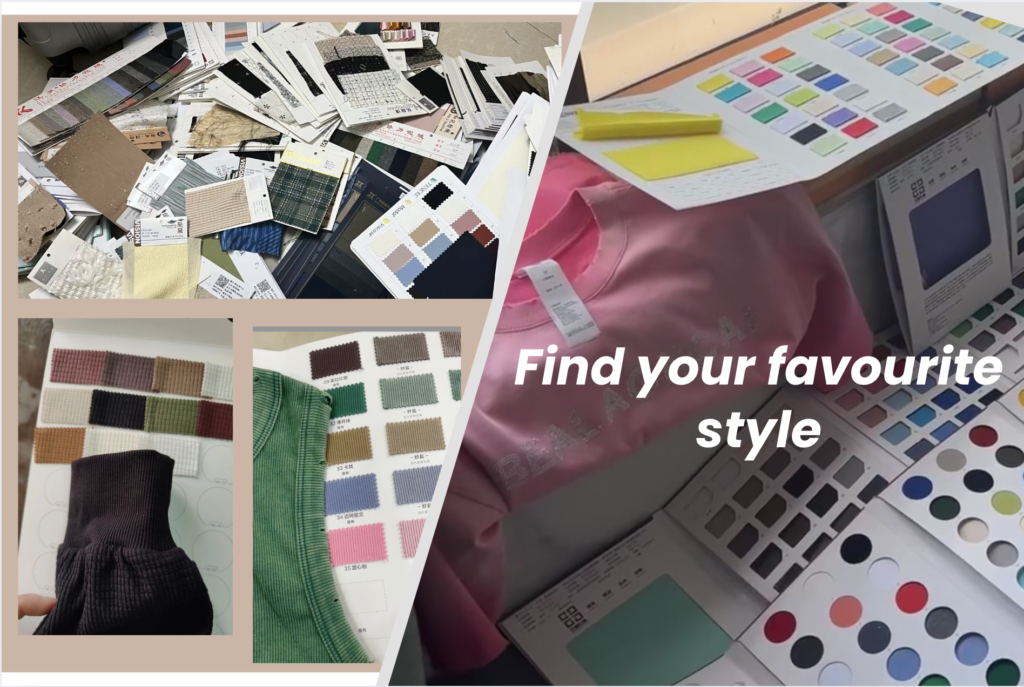

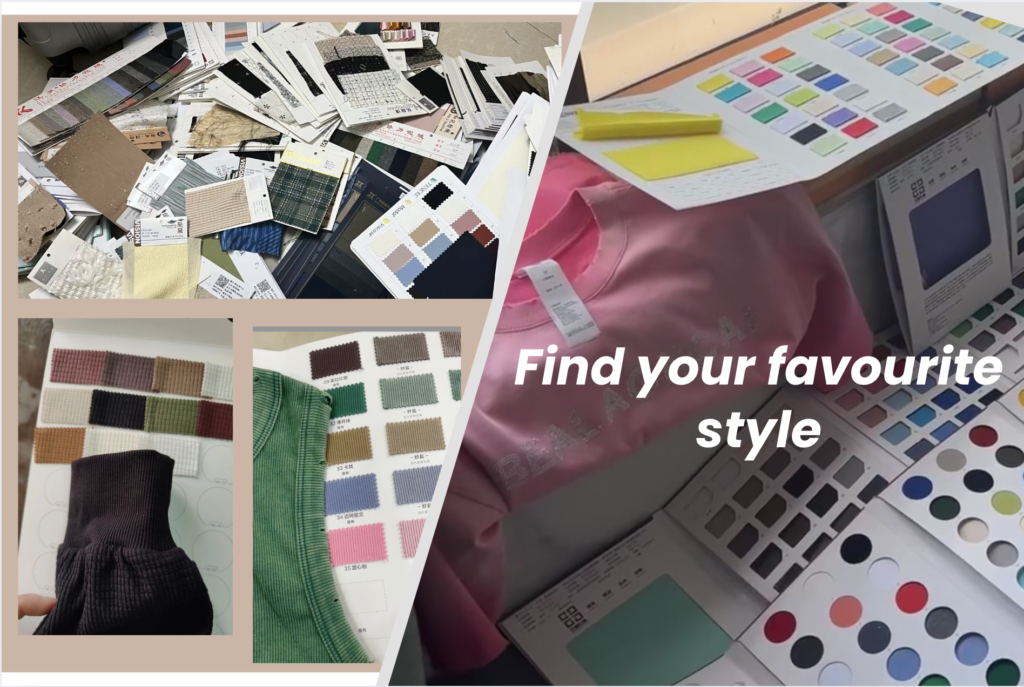

Sourcing & Purchasing: : Getting Ready for Production

Our sourcing team is always on the hunt for the best fabrics and materials. Once they’ve sourced the required materials, they pass them over to the coordinators, who send them to the clients for approval and selection. We pride ourselves on our quick response to any sourcing request. Once everything is confirmed, we make sure all materials are ready and available, so we’re always prepared to move forward.

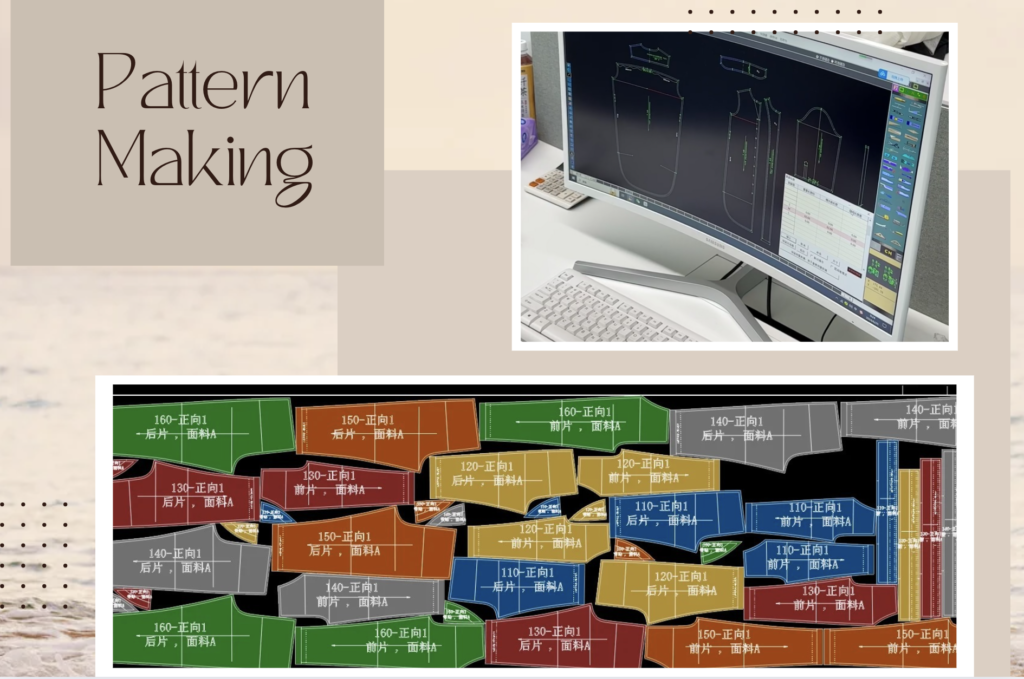

Pattern Making: Turning Designs into Reality

With tech pack, which all necessary information, from fabric specifications to construction details, pattern makers translate the designer’s vision into tangible patterns. If the client has any feedback or fit comments from earlier samples, the pattern makers adjust the patterns accordingly. They also calculate fabric usage, ensuring we make the most out of every piece of material.

Fabric Cutting: Precision in Every Cut

Once the patterns are ready, our highly skilled fabric cutters get to work. They carefully lay out the patterns on the fabric and begin cutting, ensuring each piece is precise. Accuracy is crucial here, if there’s even a small error, it can result in wasted material or a poorly fitting garment.

Sampling: Where Creativity Meets Craftsmanship

Our seamstresses stitch together the fabric pieces to create samples. This is one of the most important steps in the process. It’s where creativity and craftsmanship come together, and the design starts to take shape. Once the sample is complete, we check it against the tech pack to assess the fit, drape, and overall look. Photos are taken and samples are sent to the client for fitting.

Fit Comments and Revisions: : Fine Tuning the Design

After the client provides fit comments, we make any necessary adjustments and prepare a second sample if needed. This process continues until the client is happy with the fit and design of the garment.

Sewing and Assembly: Bringing It All Together

Once the sample is approved. We move on to the bulk fabric cutting, our machinists are ready than this involves assembling the garment, adding linings, zippers.

As the garment nears completion, final touches are added to enhance its appearance and functionality. This may include pressing, hemming, adding closures, and attaching embellishments such as buttons or embroidery, adding labels, and final packaging.

Quality Control: Ensuring Consistency

We don’t just leave quality to the end. We conduct in-line quality checks throughout the production process. Once the garment is finished, we examine each piece for imperfections or inconsistencies. This step ensures that garments meet the standards and are then approved for shipment.

End of the Day: Wrapping Up and Preparing for Tomorrow

As the day comes to a close, our team member each ensure that their equipment is cleaned and maintained, ready for another busy day tomorrow. The lights go out, but the dedication to craftsmanship and quality remains constant. Each garment that leaves our factory represents the hard work, care, and attention to detail from our entire team.

We hope this peek into our daily operations gives you a better understanding of what goes into creating the garments you wear. Stay tuned for more behind-the-scenes stories from the world of fashion!